Hooper Machine & Design

LOADING

What we do - Who we are

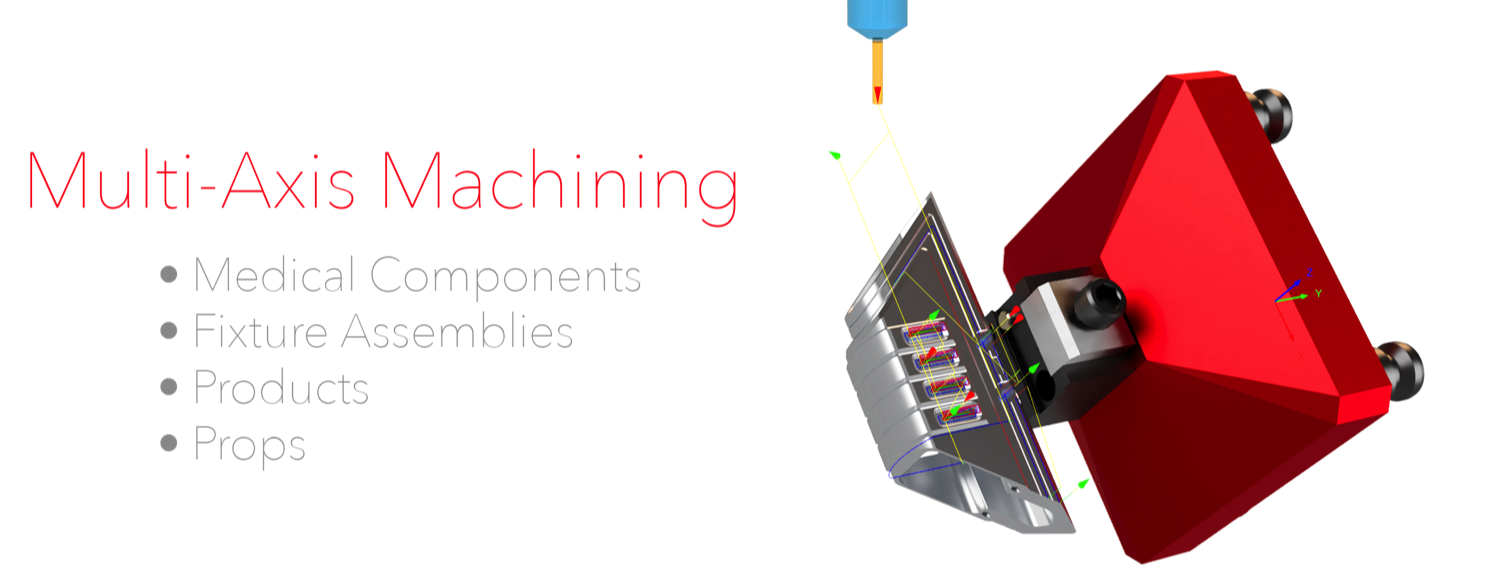

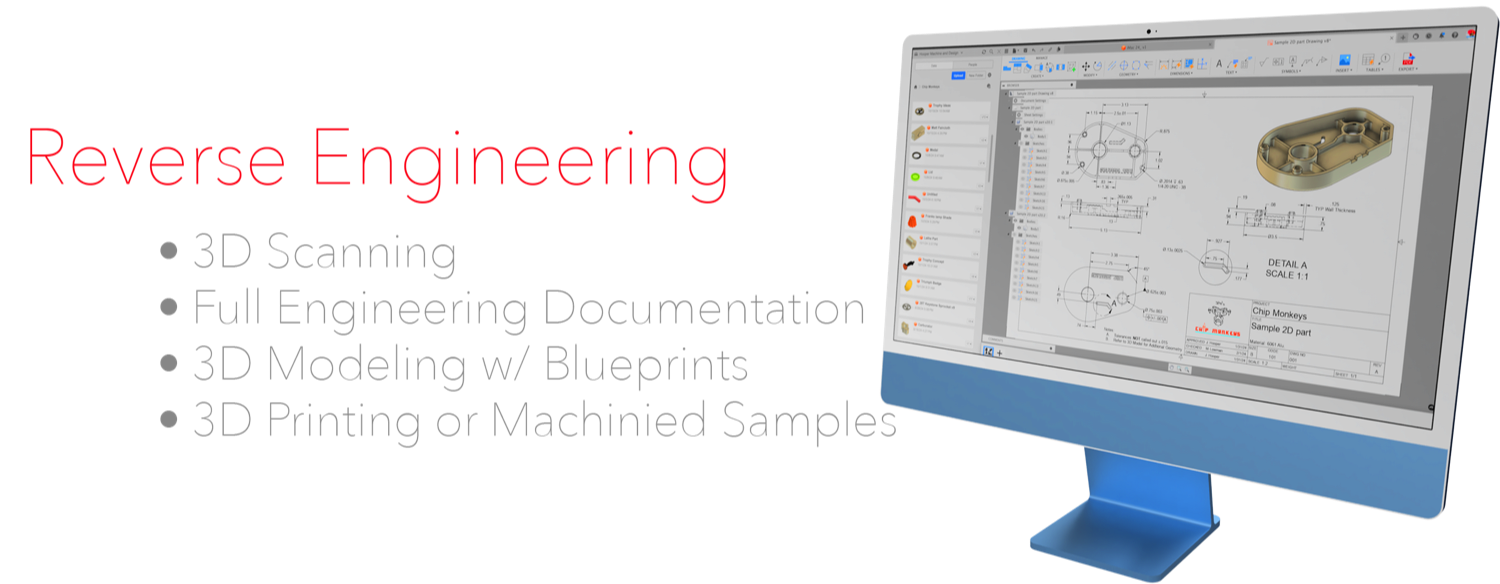

Hooper Machine & Design is a one-man machine shop run by Jeff Hooper, who brings over 25 years of hands-on expertise in machining, multi-axis CNC operations, and engineering. Jeff’s skill set extends beyond traditional machining to encompass reverse engineering, 3D modeling, and innovative design.

With a deep passion for tackling challenging projects, Jeff is the person you work with directly—no middlemen or sales teams. Whether you need precision-crafted components, manufacturing consultation, or creative solutions to complex mechanical problems, Jeff’s experience ensures efficient and cost-effective results.

At Hooper Machine & Design, you won’t just get parts; you’ll get practical insights and tailored strategies to bring your ideas to life and optimize your designs for manufacturing.

With a deep passion for tackling challenging projects, Jeff is the person you work with directly—no middlemen or sales teams. Whether you need precision-crafted components, manufacturing consultation, or creative solutions to complex mechanical problems, Jeff’s experience ensures efficient and cost-effective results.

At Hooper Machine & Design, you won’t just get parts; you’ll get practical insights and tailored strategies to bring your ideas to life and optimize your designs for manufacturing.